HIGHLIGHTS

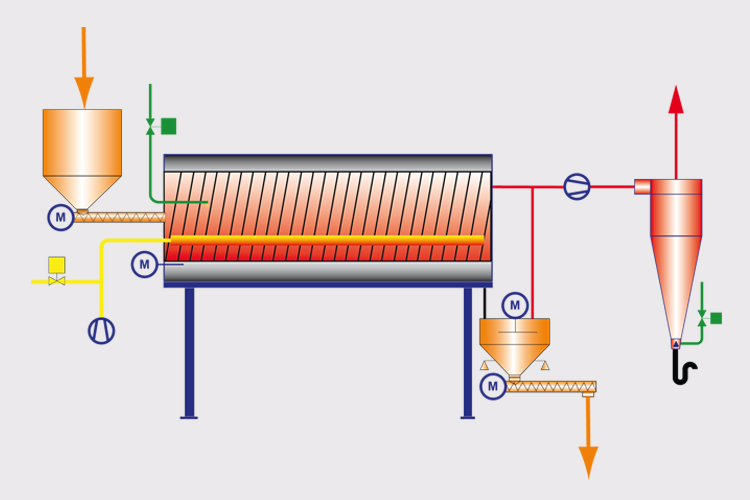

Infrared machine CBTS

What are the highlights of the infrared machine CBTS?

- Optimum shell separation from the bean

- Optimum yield of cocoa nibs

- Short treatment time in the IR drum

- Low water loss and therefore flexible beans

- Efficient use of energy through IR radiation

CAPACITIES

Infrared machine CBTS

The infrared machine CBTS is available with the following capacities:

- CBTS 20: 1000 kg/h Cocoa beans

- CBTS 40: 4000 kg/h Cocoa beans

- CBTS 60: 6000 kg/h Cocoa beans

- CBTS 80: 8000 kg/h Cocoa beans

- CBTS 100: 10000 kg/h Cocoa beans