HIGHLIGHTS

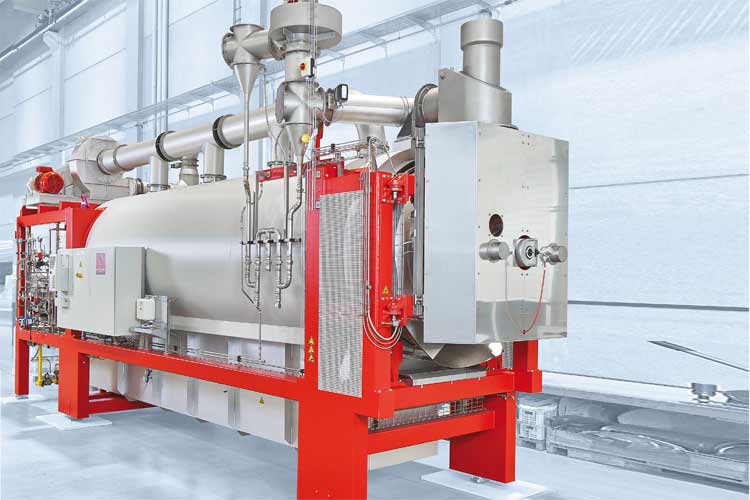

Roasting system CNRS

Here are the highlights of the roasting system CNRS:

- Flexible batch roasting system

- Sterilization during the roasting process

- Repair of taste defects

- Alkalization of the nibs

- Even energy distribution through TET

- Optimized energy consumption through burner air preheating CAPS

CAPACITIES

Roasting system CNRS

The roasting system CNRS is available with the following capacities:

- CNRS 10: 1000 kg/batch cocoa nibs

- CNRS 35: 3500 kg/batch cocoa nibs

- CNRS 50: 5000 kg/batch cocoa nibs

- CNRS 60: 6000 kg/batch cocoa nibs