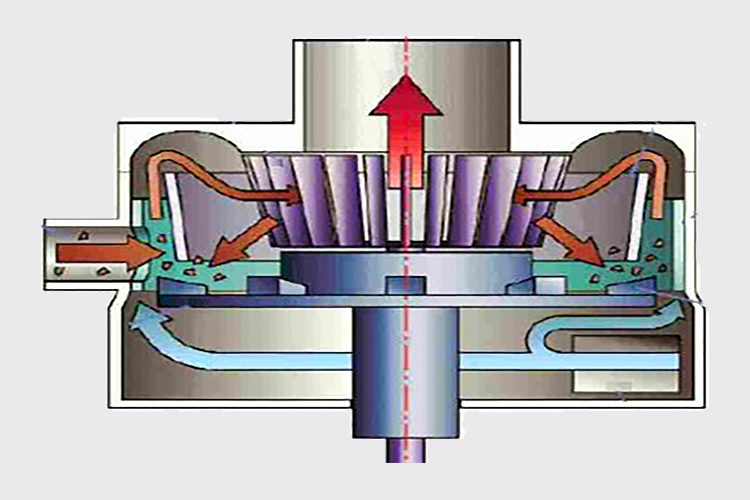

By grinding the cocoa cake, the cocoa cake is deagglomerated to the particle size present in the cocoa liquor before pressing. If further grinding is desired, this is possible at any time with the classification technology of the CCMS system.

Due to the mechanical design of the machine elements involved in the comminution, the service life of these elements is significantly longer compared to other grinding systems.

This results in shorter downtimes and lower spare parts costs.

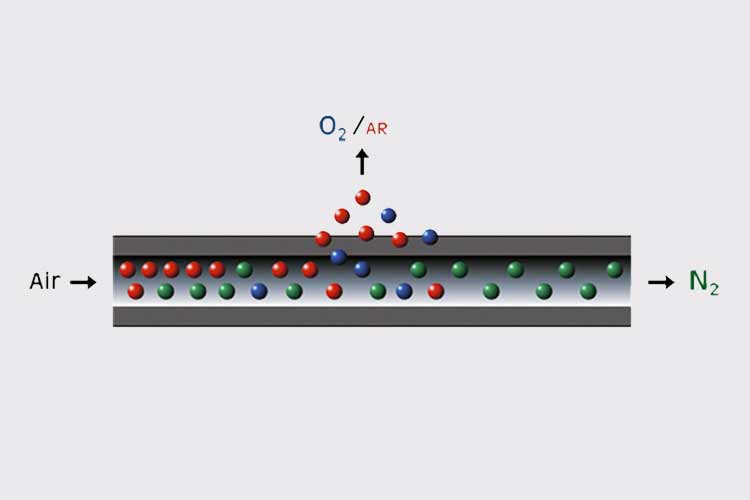

Due to the high frictional forces that are common in mechanical comminution processes, the deagglomeration of cocoa cake is also associated with a certain risk of fire or dust explosion.

The CCMS system can reliably prevent these dangers with the highest level of security. To ensure this, the composition of the circulating air flow in the air circuit of the classification mill is changed with the help of a nitrogen generator by reducing the residual oxygen content to 8-9%. With this residual oxygen content, ignition or even an explosion is absolutely impossible.