Cocoa liquor pressing

To produce cocoa butter and cocoa powder from cocoa liquor, the cocoa liquor has to be pressed. This operation separates the liquid cocoa butter and the solid cocoa components in the form of cocoa cake. By deagglomerating cocoa powder is made from cocoa cake.

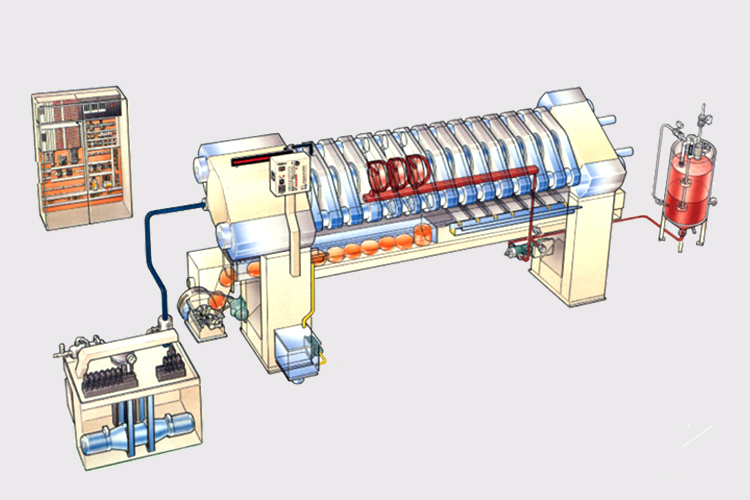

In a liquor conditioning system, the cocoa liquor is brought to the necessary temperature and the resulting viscosity, followed by the filling of the horizontally arranged press pots. The system begins to build up pressure as soon as it is being filled, thus initiating the pressing process. The pressing cycle time is depending on the desired residual fat content in the cocoa cake.

A weighing system for cocoa butter determines the amount of released cocoa butter and ends the pressing process according to the desired residual fat content.

The press opens and the cocoa cake in the form of round discs is emptied onto a cake conveyor and fed to the cake crusher.

OVERVIEW

Cocoa liquor pressing

To produce cocoa butter, the cocoa liquor has to be pressed under high pressure. This process step separates the solid components of the cocoa liquor, the cocoa particles, from the liquid components, the cocoa butter. The end products of pressing are the cocoa butter in liquid phase, and cocoa cake in solid phase. By controlling the pressing time, the residual fat content in the cocoa cake is precisely controlled.